| Sign In | Join Free | My himfr.com |

|

| Sign In | Join Free | My himfr.com |

|

| Ask Lasest Price | |

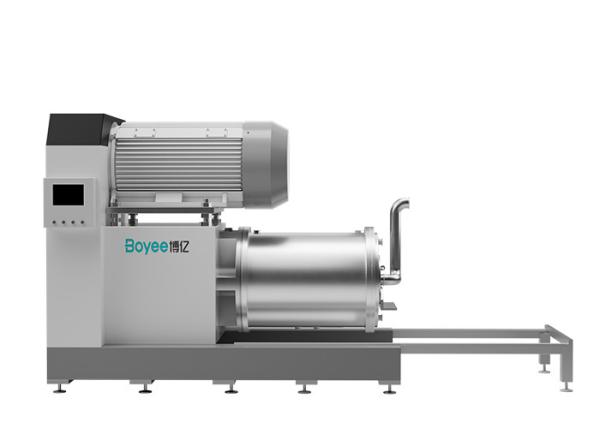

| Brand Name : | Boyee |

| Model Number : | NMM |

| Certification : | CE&ISO9001:2008 qualification |

Performance characteristics:

Ultra-fine grinding and dispersing, can be applied to micro or nano level materials with different viscosity;Ceramic(Zirconia/Silicon carbide) material of grinding cylinder can improve the purity of material without any metallic pollution;

Special mechanical seal with unique design and stable performance;

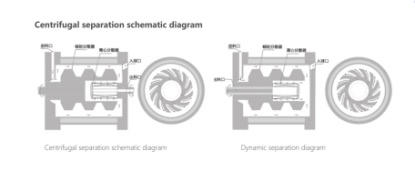

Boyee centrifugal discharging method solve the blockage problem that most mill manufacturers have at home; To make stable discharging, and a narrow particle size distribution;

An independent electric box and optimized, intelligent control system can ensure data recording and monitoring of equipment while running;The unique appearance design of the whole machine, small land occupation, and stable operation with little noise;

The smallest size of grinding medium can be 0.05mm;

The centrifugal separation method without a screen won’t block the mill;

Special cooling circuits and applications of high thermal conductivity materials can control lower grinding temperatures;High energy conversion rate.

Centrifugal Bead Mill Machine Features:

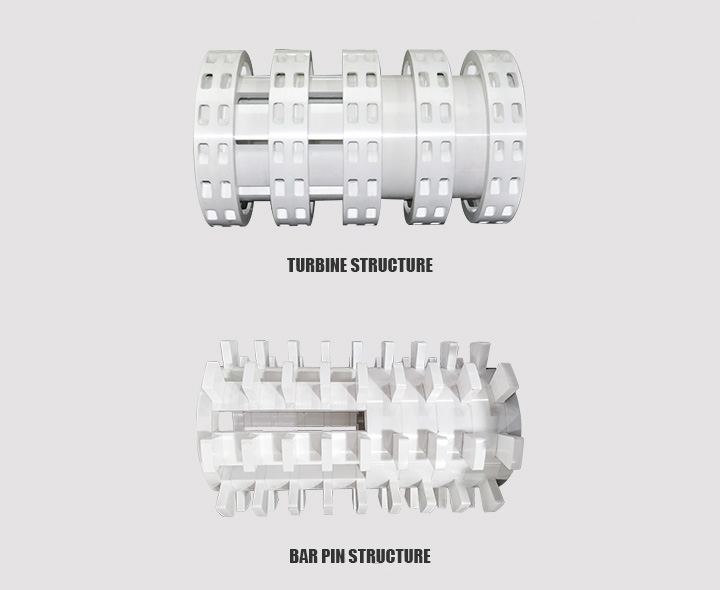

The turbine, disc or pin-type inner structure of bead mill allows high grinding efficiency. It can reach 100 nanometers for D90;

According to the process characteristic, the rotation rate of the dispersion shaft can be changed by the frequency conversion technology to get the best process parameters;Pressure and temperature automatic control devices ensure safe production;

Reasonable design for inner and outer structure allows stable performance with no vibration and noise;Ceramic and PU material is optional;

Frequency control and PLC are optional;With CE&ISO9001:2008 qualification;Dynamic or static separating system for different material to ensure smooth discharging.

Boyee TurboMax patented turbine and rod-pin grinding system can deliver energy to the grinding medium before achieving nano-level grinding and dispersion effects.

It can provide a milder and more detailed grinding effect, which can effectively prevent excessive dispersion of materials, improve grinding quality and precision, reduce loss costs, and improve production efficiency.

The rod-pin rotor structure has high linear speed, which can form continuous and strong grinding in the grinding chamber, and has a stronger impact and grinding effect on the material. It is suitable for grinding needs with difficult dispersion, high viscosity and no special requirements for the material structure.

Boyee NMM series provides material contact parts with all plastic or industrial ceramic material design to bring down metal pollution. It also provides NMM sand mills made entirely of stainless steel to meet the aseptic production needs of cosmetics, pharmaceutical and bioengineering industries.

| Model | Grinding container volume(L) | Mill machine driving power(KW) | Disperser speed(r/min) | Grinding media diameter(mm) | Machine weight(kg) | Size(mm) |

| NMM-3L | 3 | 7.5 | 0-1450 | 0.1-1 | 800 | 1400×1100×1680 |

| NMM-10L | 10 | 18.5 | 0-1460 | ≥0.2 | 1280 | 1800×1200×1550 |

| NMM-30L | 30 | 45 | 0-1000 | ≥0.2 | 1850 | 1800×1300×1800 |

| NMM-60L | 58 | 75 | 0-776 | ≥0.2 | 2480 | 3290×1478×1950 |

| NMM-90L | 98 | 75-90 | 0-776 | ≥0.2 | 3050 | 3290×1478×1950 |

| NMM-150L | 120-180 | 160 | 0-627 | ≥0.2 | 5280 | 4500×1700×2400 |

| NMM-400L | 400 | 280-315 | 0-460 | ≥0.2 | 8600 | 4600×1600×2400 |

|